Dosage systems are essential in a great amount of situations. The most important characteristics to keep in mind are: the amount of managed formulas, flexibility, error detection, precision and simplicity of programming and operating.

When looking for a dosing system with these features remember how your present expectations may change in the future and how could the considered system be adapted to the new working way.

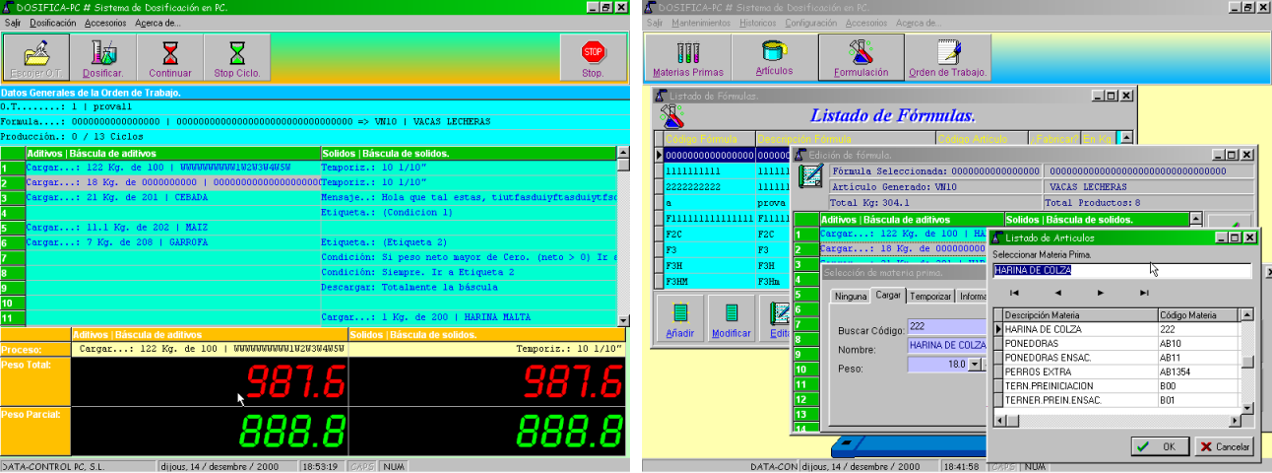

This modular dosing system consist of:

- Computer with 80 column printer.

- Dosing program under WINDOWSTM environment.

- Indicador(es) DW-XT weighing indicator(s) with RS232 or RS485 communications.

- Electrical cabinet with all the electronic modules to control input and output signals.

MAIN FEATURES

- No. of scales: from 1 to 5 (depending on the version).

- No. of products to dose with 2 rates: from 8 to 64 (depending on the version).

- No. of products to manage: Unlimited.

- No. of formulas and steps per formula: Unlimited.

- No. of positions in working orders: Unlimited.

- Available management options:

- Add, Delete, Edit, Queries,

- Reports, Find, Sorting, Fix range.

- Stock control of every product, kg produced per formula and kg spent of each raw material.

- Manual product management allowing the operator to add small components manually.

- Possibility of managing not-dosing products in the formulas.

- Automatic or Manual preact weight adjustment.

- Control output signals:

- Waiting Start of cycle,

- Coarse / fine rate,

- Unload,

- Partial Unload,

- Last cycle,

- Manual product,

- Alarms.

- Control input signals:

- Start cycle / Continue, Start / Stop,

- Pause, Unloading gate closed.

- Power failure control, allows continuing dosing after it.

- Calculation of the average cost price of the produced products.

- The configuration options are protected with a configurable PASSWORD.

OPTIONS

- Integration with our weight bridge weighing system LORRY-PC.

- Duplicity of operating keys by means of external buttons.

- RS232, RS485, Modem or ETHERNET communication with other devices.

- Communication with other PC.

- Integration with SCADA systems.

- Barcode label printing of the performed dosings by a labelling machine.

- We can modify the operating on demand.

REPORTS

- Preview of the reports on the screen.

- Products.

- Brief and detailed list of formulas.

- Working order.

- Report of finished formulas.

- Report of consumed products.

- Report of regularizations.

- Report of end of working cycle.

- Historical report of performed dosings.

- Products to be manually dosed.

- Final report of the working order.

* All information presented herein is subject to change without notice.